Industrial Automation Solutions

Custom Machinery & Equipment

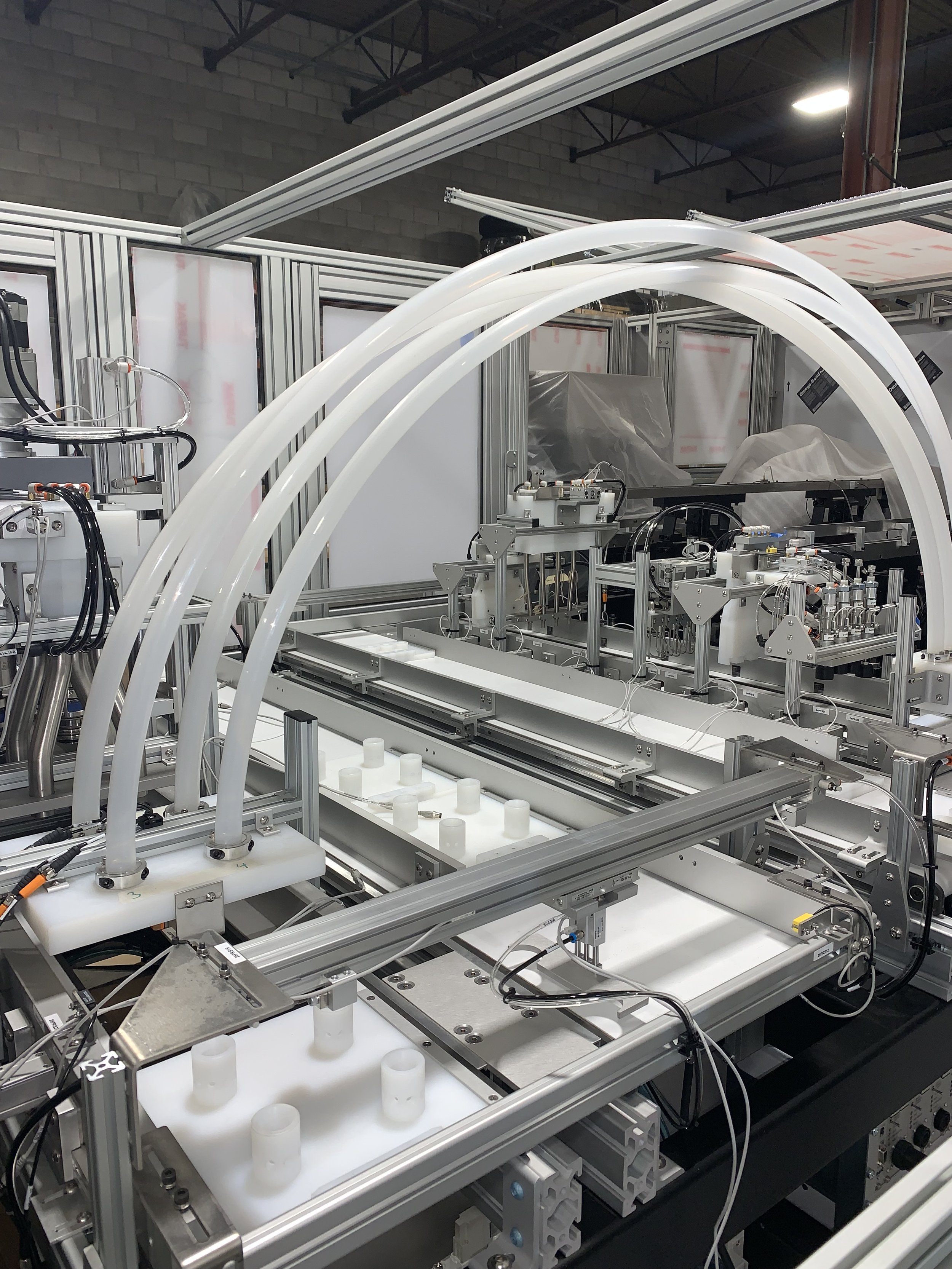

Custom Automation Machinery Engineering

Are you seeking custom-engineered automation services but lack the resources to get it done on spec and on time for your production line? RT Engineering specializes in the design and builds of high-throughput assembly equipment systems for a wide array of industries. Using synchronous, asynchronous pallet, and linear transfer systems, RT engineers automation equipment to precise motions and repeatable assembly that can be reconfigured to meet changing production demands in New England.

RT industrial automation engineering features Cartesian and SCARA robots and servo-driven manipulators with optional end-of-line inspection testing or labeling.

How RT Engineering Partners with You

To start an industrial automation engineering project, RT will form a task force consisting of mechanical, electrical, and software engineers, an operations coordinator, and a project management leader with extensive experience in industrial automation equipment & machinery. Collaborating with your team, engineers will design the automation equipment according to your throughput and quality requirements.

All designs are modeled in 3D software using SolidWorks to ensure the precision of your specifications. In addition, RT’s industrial automation services offer the development and programming of control systems to accompany mechanical systems. We understand process manufacturing and can address even the most challenging custom industrial control systems design requirements.

Key Advantages of Custom Automation Equipment

In its many forms, industrial automation can help to modernize production by utilizing devices and equipment that require minimal human interaction; it is an ideal method for New England companies that recurrently utilize repeatable operations and group technologies.

Some other benefits of automation machinery include but are not limited to:

Improve Efficiency: Streamline trouble areas that drain resources.

On-Demand Machine Shop: React quickly to demand by leveraging RT's 25,000 sq. ft. machine shop.

Maintain a Competitive Edge: Build that one-of-a-kind differentiator regardless of resource constraints.

Address Regulations Quickly: Comply rapidly with changing production regulations.

Inspection Automation Machinery

RT delivers the latest in non-contact, machine vision, and electrical probing technologies helping companies to improve overall product quality, grow their business, reduce manufacturing costs, and become more competitive. Inspection automation machine systems are designed to be flexible and adjust to different products and environmental conditions automatically.

Applications

Fiber optics gauging

Electronics

Consumer goods defect detection

Medical device assembly verification

Food processing monitoring

Character and label verification

Technologies Applied:

2D and 3D machine vision

Laser micrometers

LVDT's

Weigh scales

Intellution and RS View SCADA's

Barcode readers

Mass flow meters

Testing Automation Machinery

Applications

Electrical connectors

Cable Assemblies

Filter Integrity

Package Integrity

Laser Detection

2D and 3D Machine Vision

Assembly Testing

Technologies

Hi Pot Testers

Pressure Leak Testers

LVDT’s

Single Point Fiber Optic Sensing

Wire & Web Industrial Automation Machinery

RT designs, builds, and integrates automation equipment solutions for wire and web machine applications including:

Take-Ups (with Traverse Guides)

Pay-Offs (Non-Driven & Driven)

Capstans (Linear Belts & Drum)

Roll Stands

Extruders

Dancer Assemblies

Length Measuring Assemblies (Traction Wheel & Belt Type)

Straighteners & Caster

Life Science & Pharmaceutical Automation Machinery

The Life Sciences manufacturing landscape is rapidly changing and under constant pressure. RT Engineering works with Life Sciences companies to build industrial automated machinery that increases efficiencies, productivity while decreasing life-cycle costs. We design and build automation equipment solutions that support unique requirements for Life Sciences and Pharmaceuticals in New England and Massachusetts.

Requirements

Stainless steel for daily wash-downs and chemical cleaning

Cleanroom rated components and design

Tool-less quick changeover tooling

PLC and/pr PC based with data collection

Technologies

Rotary Indexers

Linear Indexers

Pallet/Tray conveyor feeders

Pneumatic Pick & Places

Servo Pick & Places

SCARA & Cartesian Robots

Vibratory Feeders

Part Transfer Shuttles

Conveyors indexing, flat belt, flighted, roller, o-ring, and chain attachment

Custom Assembly Industrial Automation

If you have a unique industrial automation challenge to engineer, RT is your trusted automation engineering services provider. Here are some applications and technologies RT has particular expertise in:

Application

Medical Inhalers

Automotive Switches

Paper Goods and Bindery

Electronics and Connectors

Diagnostic Tests

Filter Cartridges

Technologies

Rotary and Linear Indexers

Ultrasonic Welders

Machine Vision for Inspection and Verification

Stakers and Orbital Riveters

Thermo-Electric Sealers

Hot Melt Glue Applicators

Ink Jet and Roll Printers

Laser Welders

Engravers

2D and 3D Machine Vision

LVDT’s